Observation Software: Promote lasting change

Mobile-first. Frictionless. Put safety in the hands of your employees.

- Easily identify areas of risk and proactively implement control measures.

- Increase employee engagement to promote key safety behaviours and positive reporting.

“Feedback from employees is that the solution is simple and allows for easy reporting and since implementing, near miss and hazard identification reporting has increased by over 50% (vs. same period in 2019) and is being rolled out across other areas of the GKN Wheels & Structures business.”

Andy Jones, HSE Coordinator & System Administrator, GKN Wheels & Structures.

Still using traditional reporting?

Traditional observation and hazard reporting can often be inaccessible and impractical for your employees.

Engage your employees, improve workplace safety

Make meaningful change

Engage your employees. Promote positive behaviour. Remove all barriers for hazard, near miss, and positive observation reporting with a mobile-first approach and proactive safety management.

.png?width=1200&height=765&name=Observation%20-%20Solution%20(2).png)

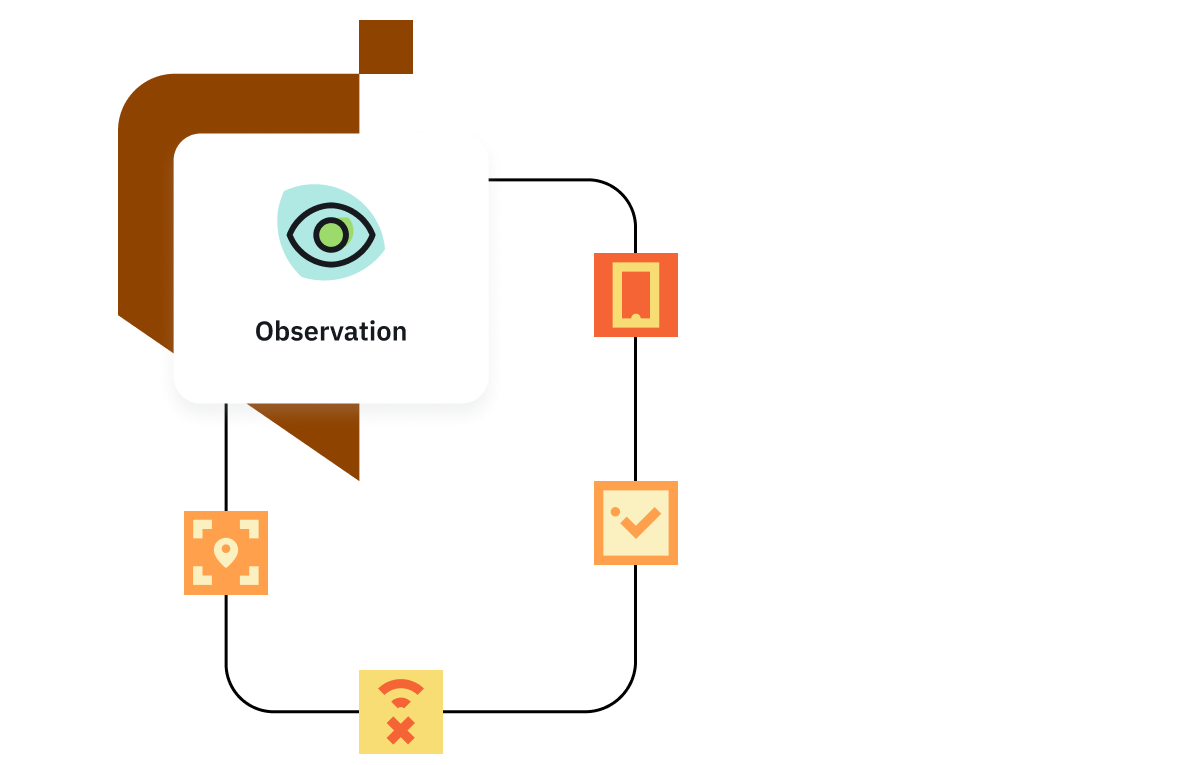

- Capture observations offline and sync whenever you’re next online.

- Track corrective and preventive actions: our powerful analytics and dashboards highlight observation impact.

Getting started is simple

Fill out the contact form

We’ll be in touch in the next 24-48 hours on weekdays to schedule a chat with one of our consultants.

Your personalized guided tour

You’ll get concierge-level service, with a customized tour to demonstrate how our software can help.

Start your journey towards a safer workplace

Discover how simple EHS can be when you’ve found the right solution for your organization.

Key features

Managers can note and review observations upon submission.

Add high, medium, or low priority status to your actions.

Attach photographs, videos and accurate locations to reports.

“The information is presented in such a way that areas of concern can easily be identified. This has enabled us to close areas of concern proactively rather than waiting for an event to occur.”

Michael Armitage, EHS Manager, Siemens

Fewer accidents happen when you can focus your time on mitigating risks

When you speak with one of our in-house EHS experts, you’ll discover the exact modules that will help streamline your organization’s current Health & Safety processes. Save time and grow a positive safety culture with the help of intuitive EHS software.

Book a demo of our software

Trusted by 10,000+ customers worldwide

With the knowledge from 90 different industries we have developed our platform to make sure it tailors to your needs.

Don't take our word for it.

-200_tmp6383.png?width=200&height=89&name=Danone-(Small)-200_tmp6383.png)

One platform. Endless EHS solutions.

Practice the best chemical safety and compliance with a cloud-based platform your employees can use from anywhere.

Reduce time-consuming health and safety training paperwork with a customizable digital learning platform.

Get a clear picture of your environmental performance data with tools that make it easier to turn insights into positive actions.